Process

Step 1

We begin by extracting the iron ore from our mines at Thakurani and Sagasahi in Odisha

Step 2

We cleanse and purify the extracted iron ore at the beneficiation facilities at Dabuna, Odisha and Kirandul, Chhattisgarh.

Step 3

We transport the refined iron to our pellet facilities through an extensive network of slurry pipelines.

Step 4

We transform iron into pellets at our port-based pellet facilities at Paradeep, Odisha and Visakhapatnam, Andhra Pradesh.

Step 5

We transport iron pellets through cargo ships to the port at Hazira in Gujarat.

Step 6

We transport iron pellets from the port to our Hazira facility through several conveyor belts.

Step 7

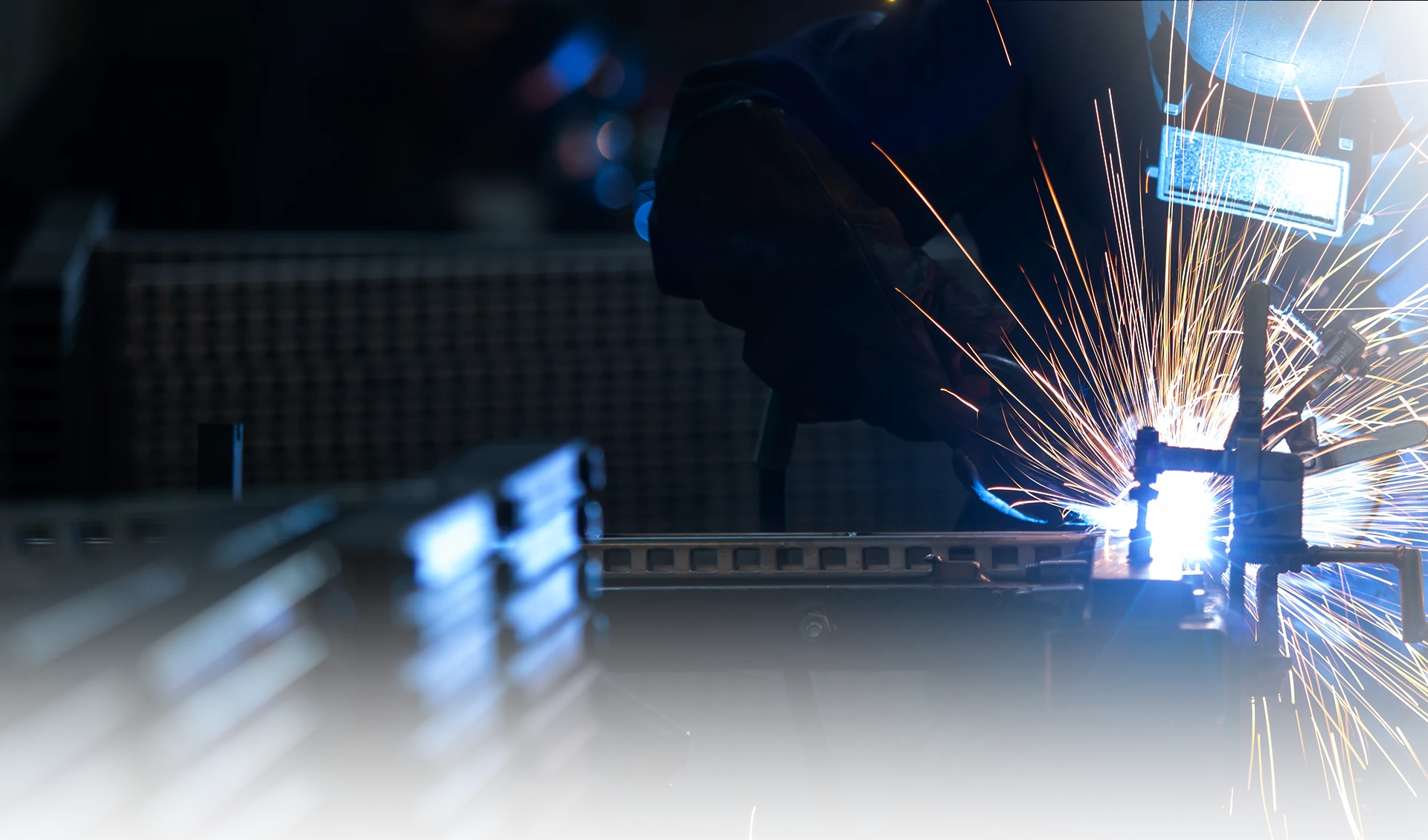

We convert iron pellets into molten iron or DRI using a blast furnace, MIDREX, and COREX.

Step 8

The liquid iron is processed through an electric arc furnace and CONARC to achieve the required steel quality.

Step 9

The steel is refined through chemical processing, converted to slabs, and ultimately rolled into a finished product.

Step 10

Through galvanizing, colour coating, and many other processes, we customize steel as per specific requirements in Pune.

Step 11

We transport value-added steel products to our service centres and hypermarts via railways or other commercial vehicles.

Step 12

We deliver steel solutions to our customers across the country - and beyond.