UNSEEN PRECISION. UNMATCHED SURFACE.

AM/NS Optima, Produced On The Advanced CGL-4 (India’s Most Advanced Galvanizing Line) at AM/NS Hazira, Sets A New Benchmark In Steel Surface With High Precision. As India’s Premium True Zero-Spangle Galvanised Steel, It Delivers Superior Uniformity Over Conventional Options. Precision-Engineered Substrates Ensure Consistent Thickness, Controlled Surfaces, And Predictable Bending.

UNSEEN PRECISION. UNMATCHED SURFACE.

SEE THE

ADVANTAGES

ADVANCED ZERO SPANGLE FINISHING TECHNOLOGY

AM/NS Optima manufacturing uses advanced finishing technology, including a tandem cold rolling mill equipped with auto shape, control, four high skinpass mills and six high tension levellers in combination, to ensure best-in-class flatness tolerances and zero spangle finishing for better end-product manufacturing quality.

HIGHER CORROSION RESISTANCE EXTENDS END-PRODUCT LIFE

The zero-spangle attribute of AM/NS Optima, coupled with skin-passing and uniform zinc coating, ensures superior corrosion resistance and enhances end-product life-expectancy. The optimum chrome passivation is designed to deliver a superior resistance to white rust.

AESTHETICALLY BEAUTIFUL WHEN PURE STEEL NEEDS TO BE SEEN

AM/NS OPTIMA delivers smoother, shiny finishes that are widely preferred in industries where the aesthetic beauty of visible steel is always on display, without the need for coatings or painting.

SUPERIOR DEGREE OF PLASTIC DEFORMATION FOR WORKABILITY

To ensure that AM/NS Optima offers superior mechanical and structural quality, for end-product forming and working utilisation, stringent process control is maintained throughout the manufacturing cycle. This stringent quality control also ensures resilient zinc-coating adhesion during metalworking.

SUPERIOR PAINT ADHESION ACROSS AGGRESSIVE CONDITIONS

AM/NS Optima with its true zero-spangled surface provides better adhesion substrate for end-products with painting requirements, compared to standard or suppressed spangled galvanised steel.

LEAD-FREE FOR A SAFER, MORE ECO-FRIENDLY CHOICE

AM/NS Optima is manufactured lead-free making it RoHS compliant and a safer, more eco-friendly steel choice.

STRONG TECHNICAL AND R&D SUPPORT

Back by deep material expertise and application engineering to support design decisions, process optimisation, and long-term performance.

TIGHT TOLERANCES FOR HIGH PRODUCTION EFFICIENCY

AM/NS Optima is engineered for dimensional consistency that improves line stability, reduces rework, and supports efficient, cost-controlled manufacturing.

APPLICATIONS

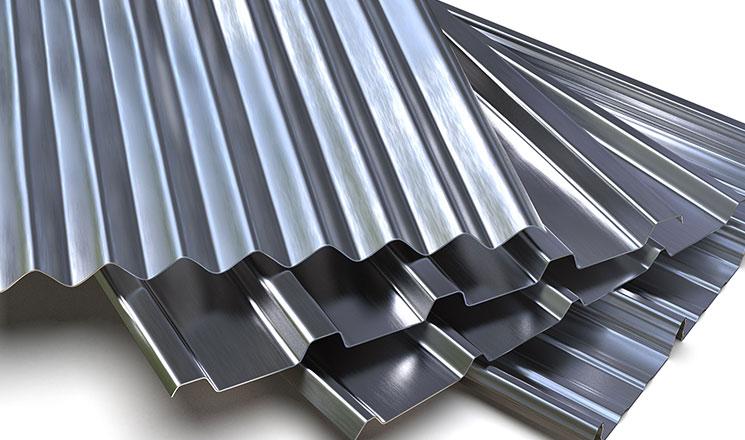

Corrosion resistance, excellent paint adhesion, suitable for outdoor conditions

Thickness: 0.50 - 0.80 mm

Steel Grade: GPL, GPD, GPEDD, GPIF

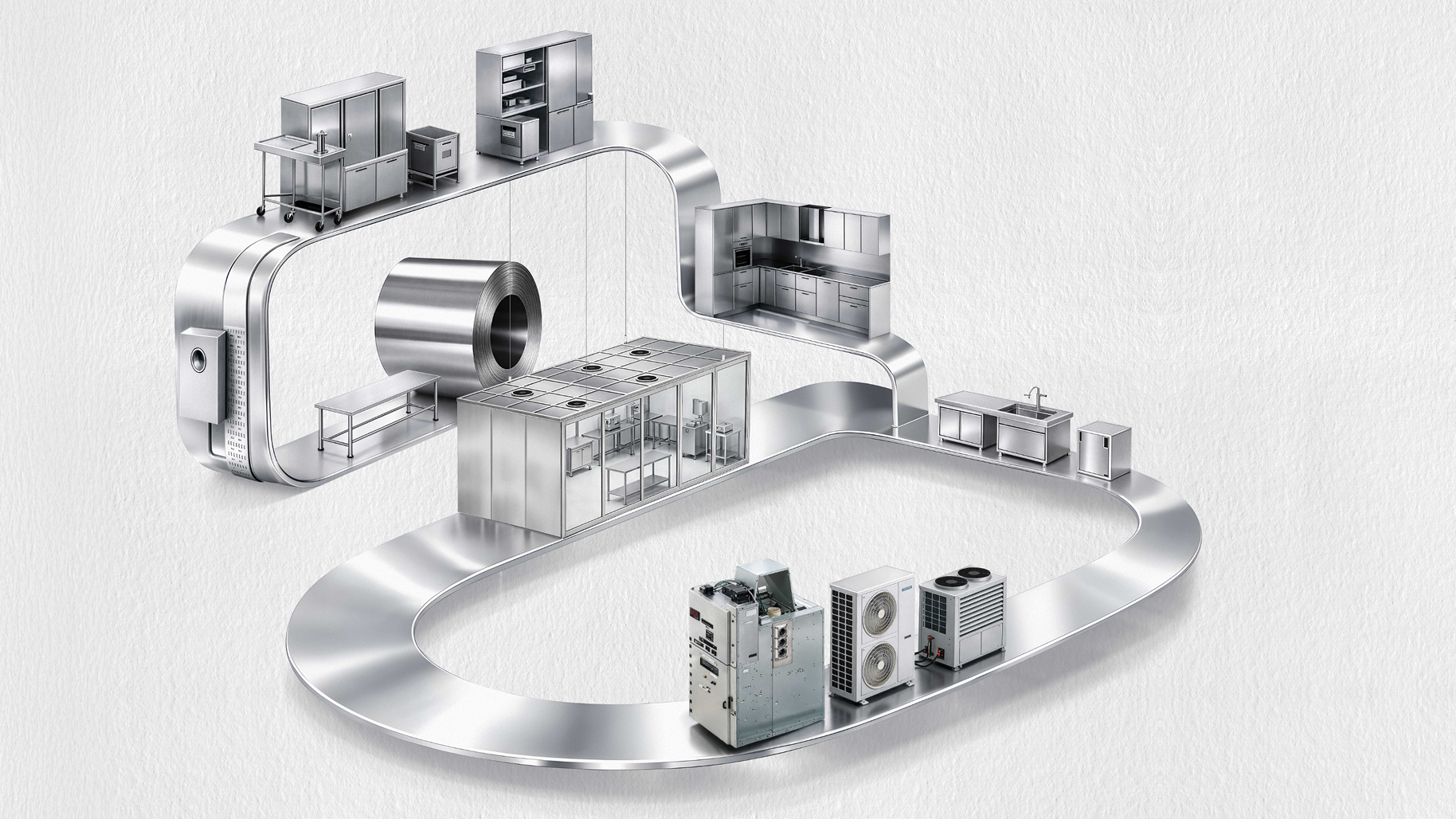

Smooth Zero-Spangle Finish, Excellent Paint Adhesion, Corrosion Resistance

Thickness: 0.40 - 0.60 mm

Steel Grade: GPL, GPD

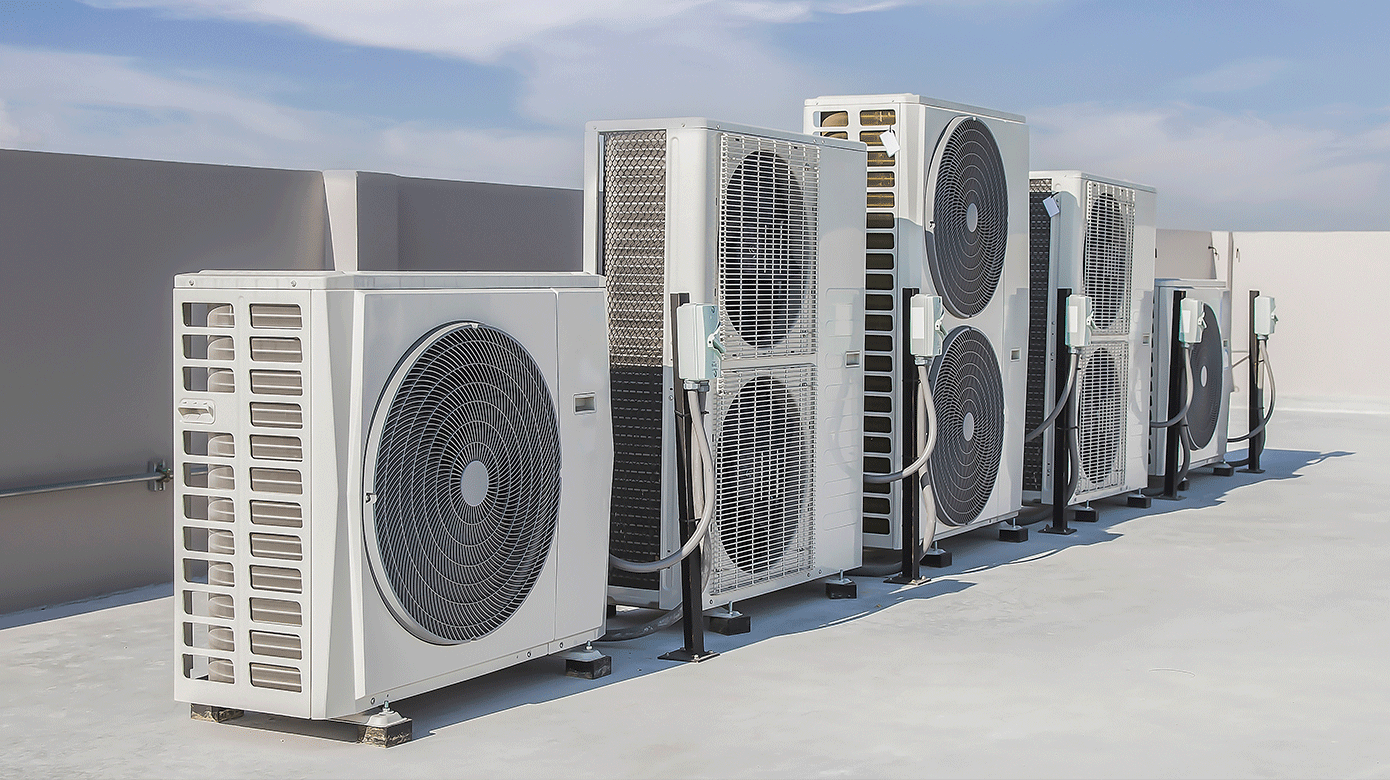

High Strength, Humidity Resistance, Easy Assembly

Thickness: 0.50 - 0.80 mm

Steel Grade: GPL, GPD

Premium Finish, Formability For Bends And Folds

Thickness: 0.50 - 0.70 mm

Steel Grade: GPL

Scratch-resistant Surface, Smooth Finish For Aesthetics

Thickness: 0.40 - 0.60 mm

Steel Grade: GPL

Thickness (mm)

0.4 - 3.2 mm

Width Range

750 - 1650 mm

Coating

up to 450 GSM*

Standards

IS277/ ASTM653/ JISG3302/ EN10346

Steel Grade

Forming grades - DQ, DDQ, EDD/IF Structural Grades - GP240 - GP550

Surface Type

Skin-pass

Surface Treatment

Chrome 3/ Chrome 6/ Chrome-free passivation/ oiled/ unoiled

| Designation | Grade | C Max | Mn Max | S Max | P Max | Ti Max |

|---|---|---|---|---|---|---|

| GP | Ordinary | 0.25 | 1.70 | 0.045 | ||

| 0.050 | --- | |||||

| GPL | Drawing (Lock Forming) | 0.12 | 0.50 | 0.035 | ||

| 0.040 | --- | |||||

| GPD | Deep Drawing | 0.10 | 0.45 | 0.030 | 0.025 | --- |

| GPED | Extra Deep Drawing | 0.08 | 0.40 | 0.030 | 0.020 | --- |

| GPIF | Interstitial Free (Stabilised) | 0.06 | 0.25 | 0.020 | 0.020 | 0.15 |

| GP230 | Structural Steel Grade 230 | 0.20 | 1.35 | 0.040 | 0.040 | --- |

| GP250 | Structural Steel Grade 250 | 0.20 | 1.35 | 0.040 | 0.050 | --- |

| GP275 | Structural Steel Grade 275 | 0.25 | 1.35 | 0.040 | 0.050 | --- |

| GP300 | Structural Steel Grade 300 | 0.25 | 1.35 | 0.040 | 0.050 | --- |

| GP350 | Structural Steel Grade 350 | 0.25 | 1.35 | 0.040 | 0.050 | --- |

| CLASS-1 | CLASS-2 | |||||

| GP350 | Structural Steel Grade 350 | 0.25 | 1.35 | 0.040 | 0.050 | --- |

| CLASS2 | CLASS-2 | |||||

| GP450 | Structural Steel Grade 450 | 0.25 | 1.60 | 0.040 | 0.050 | --- |

| GP550 | Structural Steel Grade 550 | 0.25 | 1.70 | 0.040 | 0.050 | --- |

| Designation | Name | Yield Stress | Tensile Strength | Elongation, Percent A Min | |

|---|---|---|---|---|---|

| Name | MPa | MPa | L.=80mm | L,=50mm | |

| GP | Ordinary | ||||

| --- | |||||

| GPL | Drawing(Lock Forming) | 350 max | 450 max | 25 | 25 |

| GPD | Deep Drawing | 280 max | 430 max | 26 | 27 |

| GPED | Extra Deep Drawing | 260 max | 430 max | 28 | 31 |

| GPIF | Interstitial Free (Stabilised) | 240 max | 370 max | 34 | 36 |

| GP230 | Structural Steel Grade 230 | 230 min | 310 min | 18 | 20 |

| GP250 | Structural Steel Grade 250 | 250 min | 360 min | 18 | 20 |

| GP275 | Structural Steel Grade 275 | 275 min | 380 min | 18 | 20 |

| GP300 | Structural Steel Grade 300 | 300 min | 400 min | 18 | 20 |

| GP350 | Structural Steel Grade 350 | 350 min | 420 min | 12 | 13 |

| CLASS-1 | CLASS-1 | ||||

| GP350 | Structural Steel Grade 350 | 350 min | --- | 12 | 13 |

| CLASS2 | CLASS-2 | ||||

| GP450 | Structural Steel Grade 450 | 450 min | 480 min | 8 | 9 |

| GP550 | Structural Steel Grade 550 | 550 min | 570 min | --- | --- |

Get to know more

If you would like to discover our product in detail, simply download the brochure

Send Enquiry