Smart Manufacturing of Mild Steel Plates: Trends in AUtomation and Quality Control

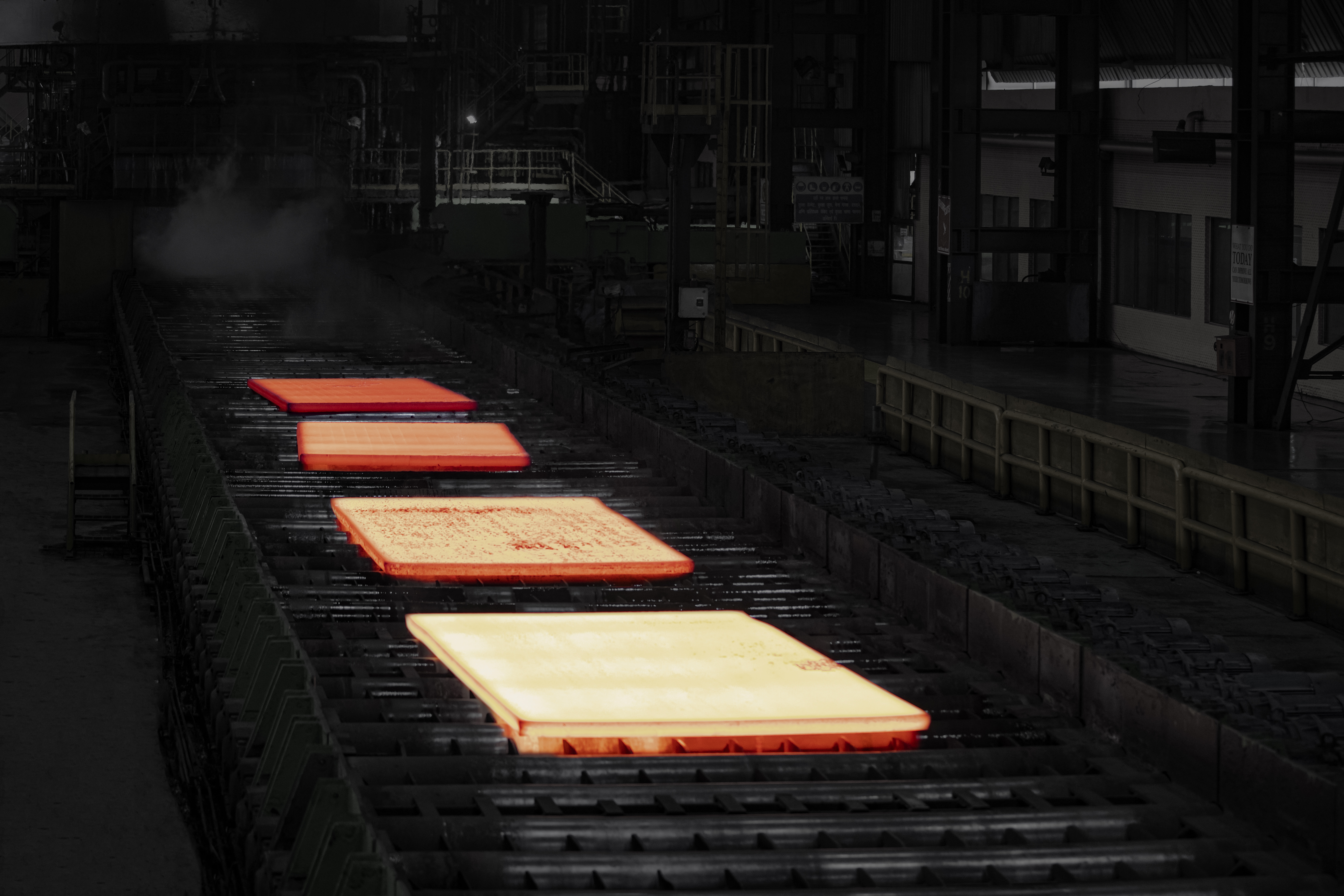

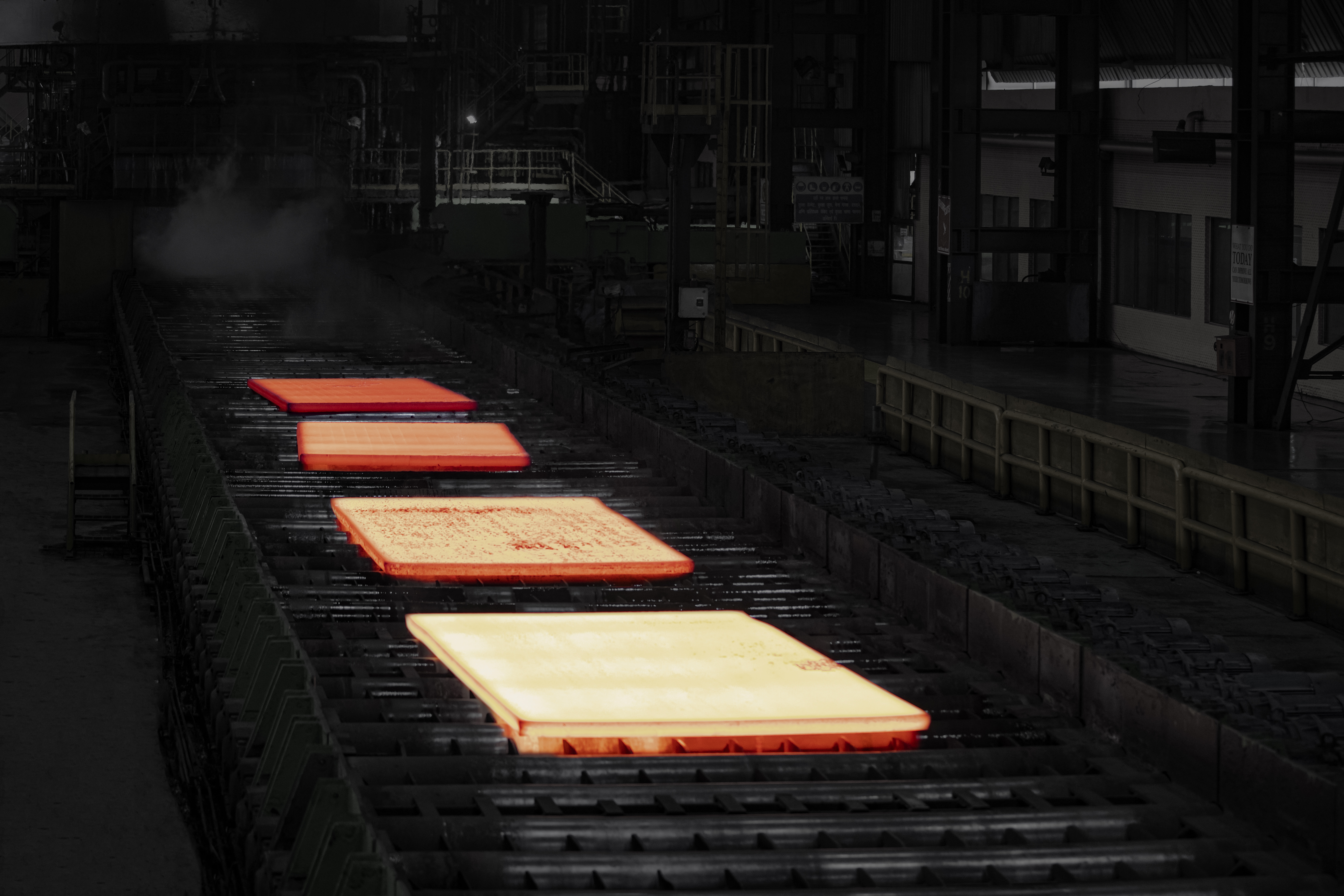

Steel plates are leading the way in adapting smart manufacturing to improve their efficiency, quality, and sustainability, Traditionally known for their versatility and durability, heavy-duty steel plates ensure higer productivity and better safety.

Automation's Role in Today's Factories

This is the era of automation in manufacturing, and intricate control operations are in place. Let's take rolling mills, for example, precise sensors are continuosly monitoring steel plate thickness, and it's interesting to see these devices flagging deviations.

Automation helps in the completion of the rather repetitive tasks, and IoT connectivity links each step of the process. The type plates varies depending on the industry, and by programming digital systems, manufacturers can allow for smoother scheduling, faster turnaround, and greater consistency across large batches.

Evolving Strategies for Quality

There is no tikme for just manual inspection in this day and age, making continuous and smart tracking a necessitiy, along with manual inspections. Mild steel plates production and manufacturing always need to be monitored so that their quality isn't compromised.

The process ensures that, even if there's a slight variation in the thickness of the mild steel plates or if there are problems with the surface quality, the staff and machines can effectively get started on dealing with the same.

If recurring flaws exist, they are solved before becoming a problem. This method significantly reduces waste and downtime. Predicting equipment needs and/ or material tweaks and being accurate about them has become easier.

Ustainability and Smarter Resource Use

SMart manufacturing of steel platese is tied to sustainability. Energy optimisation is a priority in these times, and thanks to smart technologies, it's possible to monitor consumption patterns and reduce emissions. These plates support many industries, and adopting eco-friendly practices has a huge impact.

AI-powered energy management systems can predict the required furnace temperature or rolling pressure. Recycling scrap for making usable materials has lowered both costs and the carbon footprint, giving manufacturers a precious competitive edge in the market and making progress towards their green goals. Additionally, the quality of the material also stays intact.

WHat Does the Future Hold?

There will be no end to the innovation in steel plates, The push toward AI and ML-powered production allows for real-time adjustments based on the customer's needs. Small-scale production runs are now cost-effective thanks to automation, and that is owned to proper tracking.

Again, with proper tracking, eevry plate, be it for MSMEs or major corporations, can be traced from the raw input to the finished product. This level of transparency builds trust.

Wrapping Up

The industry is moving towards a direction where efficiency and innovation are the same, improving the production of steel in every way possible. As industries demand stronger, lighter, and precise materials, manufacturers' commitment to adopting smart technologies will only continue to be tested more.

AM/NS is always on the lookout to stay ahead, and the right investment not only lies in steel plate, but also in people and precessess for innovation at every production stage.

Explore our latest Post