Local Steel Mills vs Global Suppliers: Who Offers Better MS Plate Value

Procurement leaders do not buy on price alone. They buy certainty, repeatable quality, and delivery that protects schedules. India now operates mature plate facilities with advanced controls and application depth. That reality reshapes the question. For MS plates, which delivers better value to an Indian project today, local steel mills or global suppliers?

What "Value" Means for MS Plates

Value is total performance over the full lifecycle, not only the unit rate. For steel plate in India, assess value on five anchors:

- 1. Mechanical reliability that matches grade, heat treatment, and test benchmarks

- 2. Dimensional control control that avoids rework, especially thickness and flatness

- 3. Lead time and predictability across the entire order profile

- 4. Customisation in length, width, supply condition, and inspection scope

- 5. Total landed cost, including freight, duties, finance, storage, and the cost of delay.

Where Local Mills Create Advantage

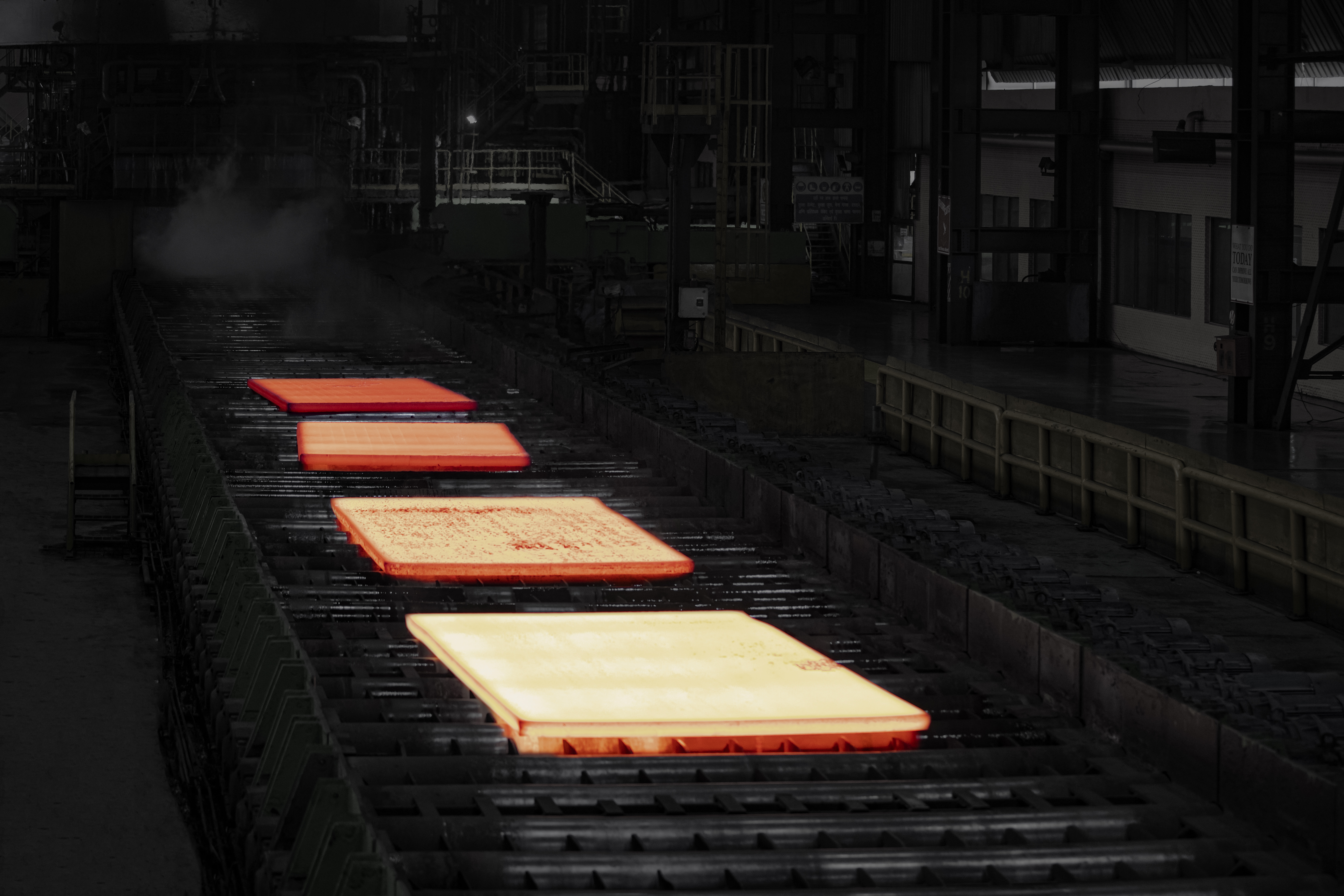

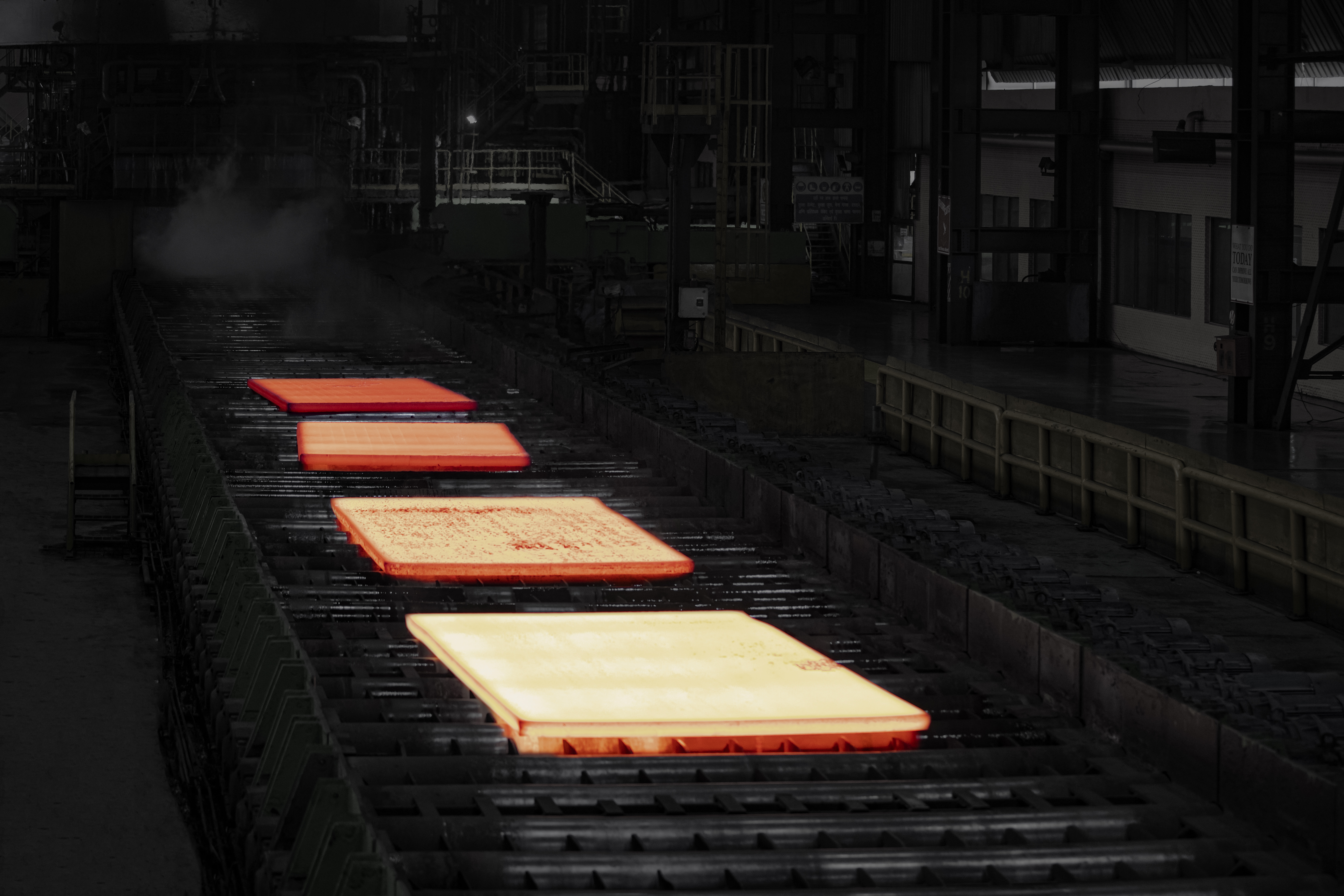

Local plate producers have invested in heavy plate manufacturing with TMCP, normalised, and Q+T routes, along with robust Level 2 automation and HAGC thickness control. For buyers, this converts directly into fewer surprises and a shorter purchase-to-production cycle.

- 1. Faster lead times and esier expediting are critical when sites need plates to feed weld bays without idle time.

- 2. Wider plate option that reduce joints and cut weld hours, a hidden but powerful cost lever.

- 3. Application support from metallurgist and welding engineers who speak the same language and time zone

- 4. Better responsiveness to late design changes, including cut-to-length or tighter thickness windows.

These strengths compound when the scope includes heavy steel plate for bridges, penstocks, wind tower, shipbuilding blocks, and yellow goods. The more complex the fabrication, the more local agility matters.

When Global Suppliers Make Sense

Global suppliers remain highly relevant in three scenaarios:

- 1. Niche approvals or client-mandated make for marine, offshore, or highly specialised grades

- 2. Short tactical gaps where a single plate size or specification is unavailable locally in the required window.

- 3. Projects that need small lots of unusual thickness or narrow tolerances for pilot builds

If one of these cases applies, global sourcing can be the cleanest route. The decision must still weigh finance costs, port handling, insurance, and the risk that becomes slower to resolve.

Human Oversight That Protects Your Project

Human oversight is not a formality. It is risk control that control that keeps a good decision from slipping. Build it in at each step

- 1. Align welding procedures with the actual supply condition, whether TMCP, N, or Q+T

- 2. Inspect heat-wise MTCs early, confirm test locations, and set a retest path before dispatch

- 3. Run third-party inspection for critical lots, and include witness points on ultrasonic testing or impact testing

- 4. Lock a change protocol for thickness and length so the supplier can react without resetting the schedule

A Practical Decision Framework

Use this quick framework before you place the order for MS plates:

- 1. Define fitness for use, not only grade and thickness

- 2. Quality dimensional economics, wider plates can remove joints and save hours

- 3. Compare real lead time, not quoted lead time, against your project's critical path

- 4. Test service model, who answer when a weld coupon underperforms during qualification

- 5. Price the total landed cost, including interest, storage, and any contingency for delay

- 6. Decide on inspection scope, then keep records heat-wise for clean traceability

Bottom Line

For mainstream infrastructure, energy, construction equipment, and shipbuilding work in India, local steel mills generally deliver the best overall value. The reasons are practical, faster availability, consistent quality control, lower risk of delay, and engineering support that adapts to field realities. Global suppliers still matter when a project demands a rare grade or a mandated make. Treat that as a target exception, not the default.

The smartest path is diciplined and human-led Start with capable Indian heavy plate manufacturing, benchmark imports against a clear spec gap, and hold every option to the same oversight standard.

Explore our latest Post