Heavy Steel Plates vs. Alloy Plates: Which One Fits Your Project?

Alloy steel plates consists of elements like iron, carbon, nickel, and other materials. The constituion of these elements in the metal gives the same its unique properties. Some alloys have a higher corrosion resistance compared to others. They're generally used in high-stress manufacturing and construction.

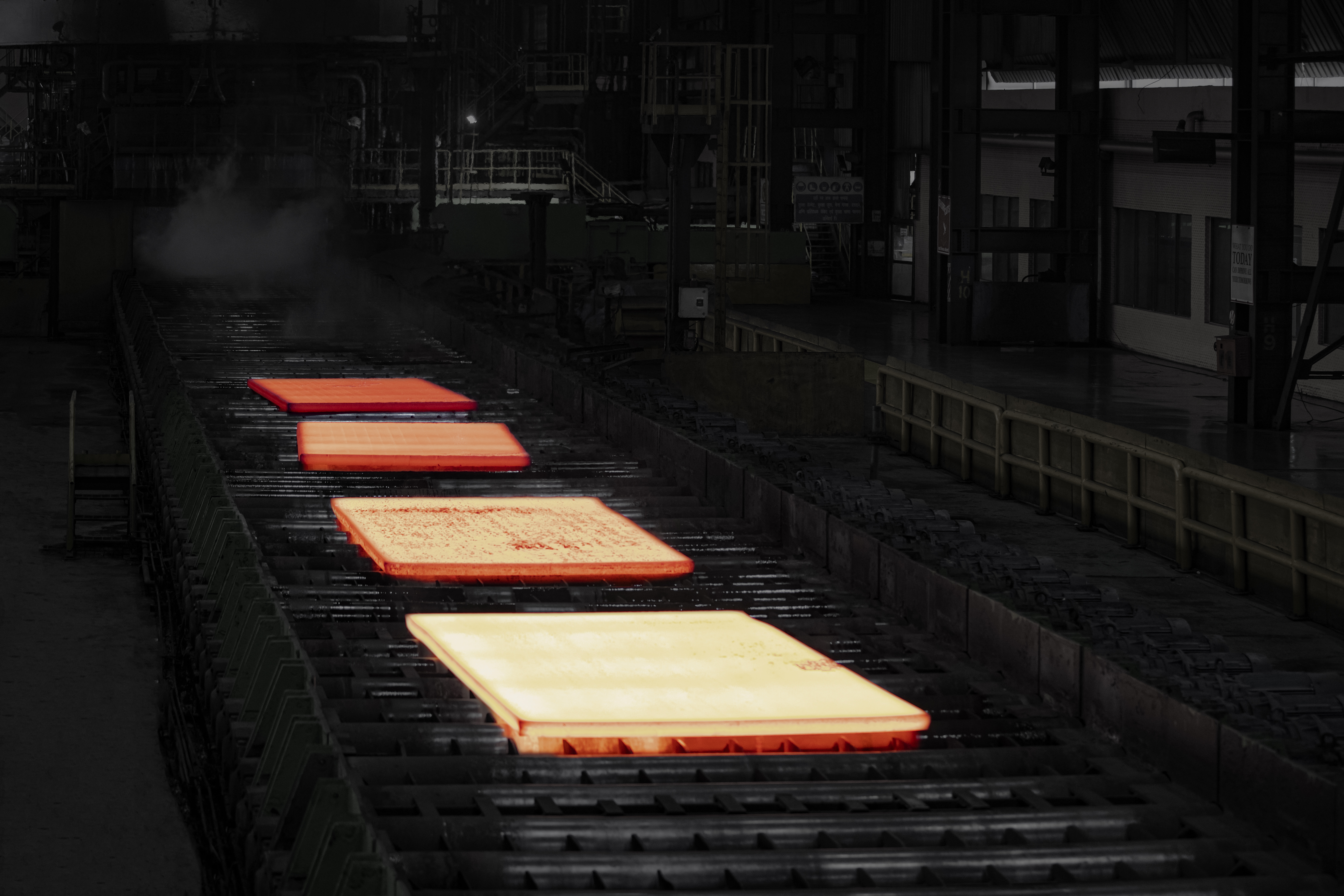

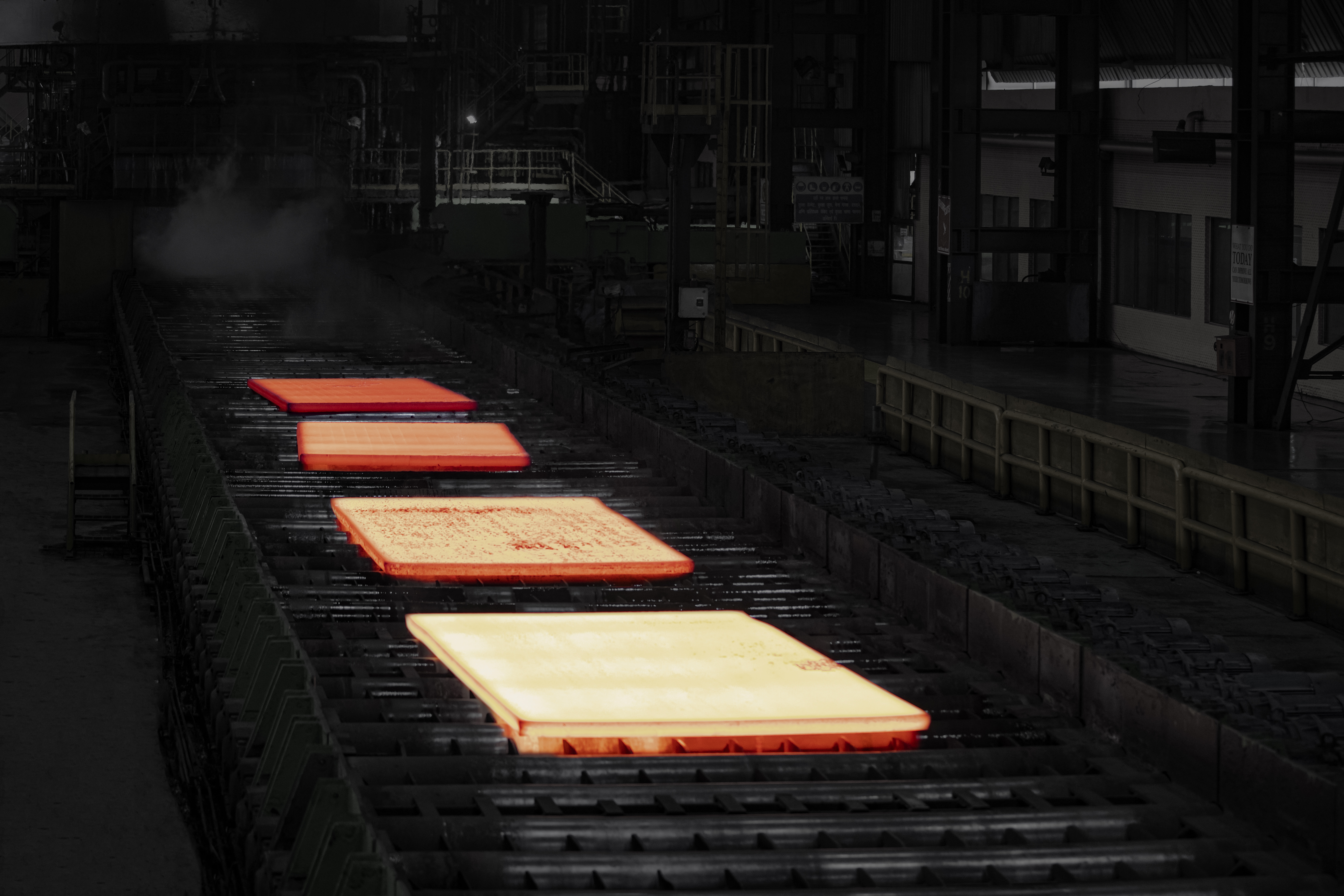

A heavy steel plates company, on the other hand, makes steel plates in thickness of 6 to 200mm. Heavy plates give structure and a proper foundation to bridges.

The Key Properties

Steel plate thickness is important designers the flexibility to tailor structural strngth exactly where needed. Alloys boast of having tensils strength and superior heat tolerance. These are just one of their properties. The rest are in the table:

| Property | Heavy Carbon Steel Plates | Alloy Steel Plates |

| Strength / Hardness | High; increased carbon adds hardness but may reduce ductility | Turnable; allows balance of hardness with toughness |

| Corrosion Resistance | Low; typically requires coatings or galvanization | Chromium/nickel, stainless variants, resist rust naturally |

| Weldability / Machinability | Excellent, especially low-carbon grades | High-alloy steels require specialized welding techniques |

| Cost | Lower, widely available | Higher, depending on alloy content and processing complexity |

| Applications | Structural frameworks, heavy beams, and general fabrication | Pressure vessels, pipelines, high-temperature equipment, and machinery parts. |

Why Choose Heavy Steel Plates?

There are many steel companies in India specialising in heavy steel plates, and AM/NS's projects include boilers, pre-engineered buildings (PEBs), and more.

High Strength

Heavy steel plates are popular beacuse they offer additional strength. They can excel under heavy static loads and can support a multi-storey building or mechanical structures. These are applications where rigidity is important.

Ease of Fabrication and Cost Efficiency

A reputed MS plate supplier will provide heavy steel plates that can be welded and cut easily. they have good plasticity and just as good resistance to wear and tear. For this reason, these plates have a lower cost and faster turnaround for high-scale projects.

The Best for General Construction

Havy steel plates can withstand extreme heat and are resistant, and these plates meet practical needs without much complexity. They're used for railroad stations, the shipbuilding sector, and more.

Why Opt for Alloy Steel Plates?

We addressed the reasons for choosing heavy plates; now we'll talk about why alloy plates are used.

Durability

Alloy steel plates are preferred for being durable, making them the best for heavy-duty industrial applications. This makes alloy the best projects requiring heavy loads or materials that withstand high levels of stress and strain.

Low Maintenance

Alloy plates have low maintenance requirements and have minimal upkeep comapred to other materials, such as stainless steel. This reduces the labour costs associated with regular maintenance. Projects where alloy plates are used better aesthetics and performance.

Cost-Effectiveness

Alloy plates are an affordable option, but that doesn't mean that the quality of the alloy will be inferior. The right supplier will make sure that the alloy won't be that expensive and will keep your project long-lasting.

Conclusion

Both heavy steel plates and alloy steel plates have their strengths; it all comes down to what your project demands. Large structural work needs heavy plates.

If your project calls for durability in extreme conditions, alloy plates are worth the investment. The right choice will give you just performance, but peace of mind for years to come.

Explore our latest Post