Choosing the Right MS Plate Thickness: A Complete Guide for Fabricators

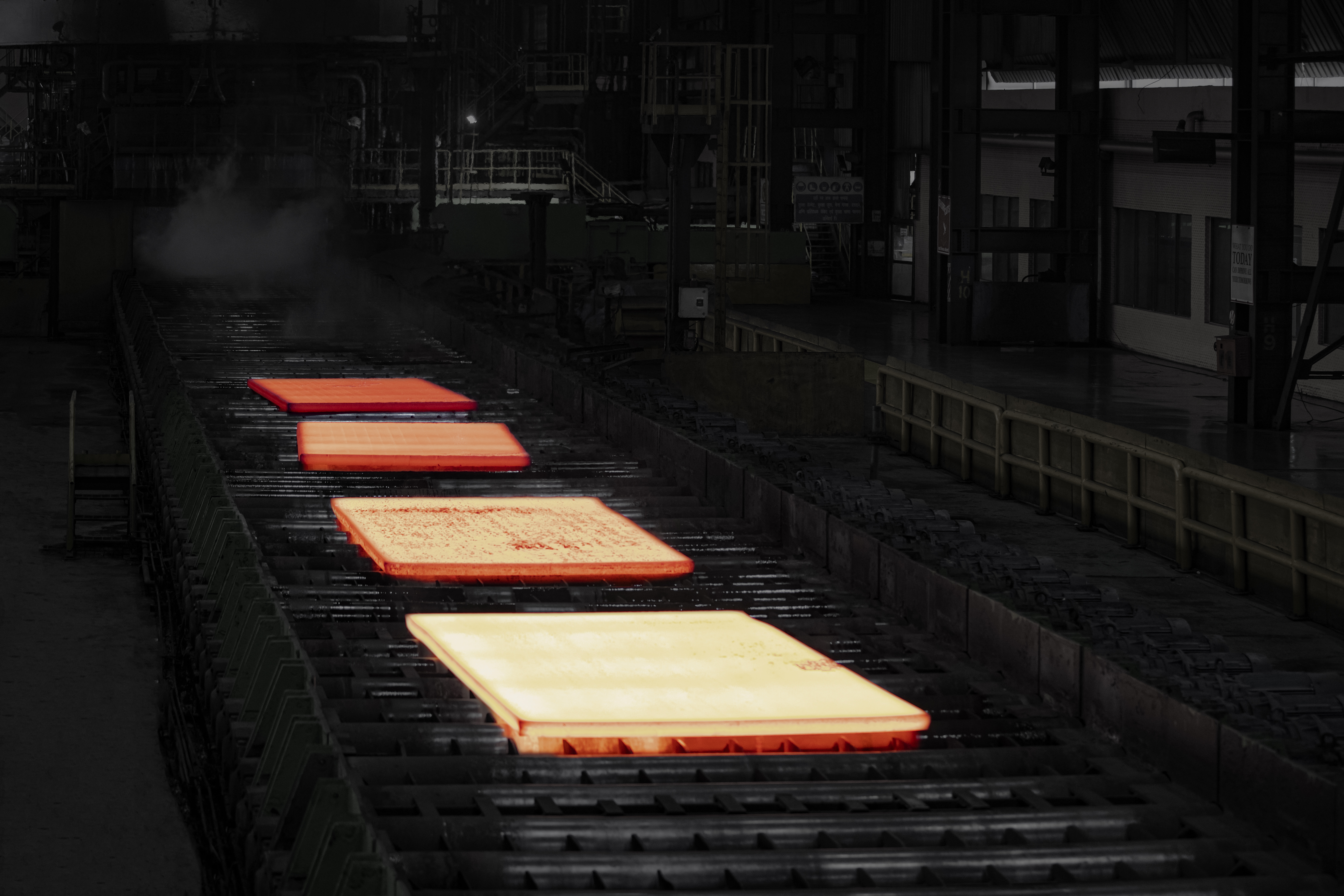

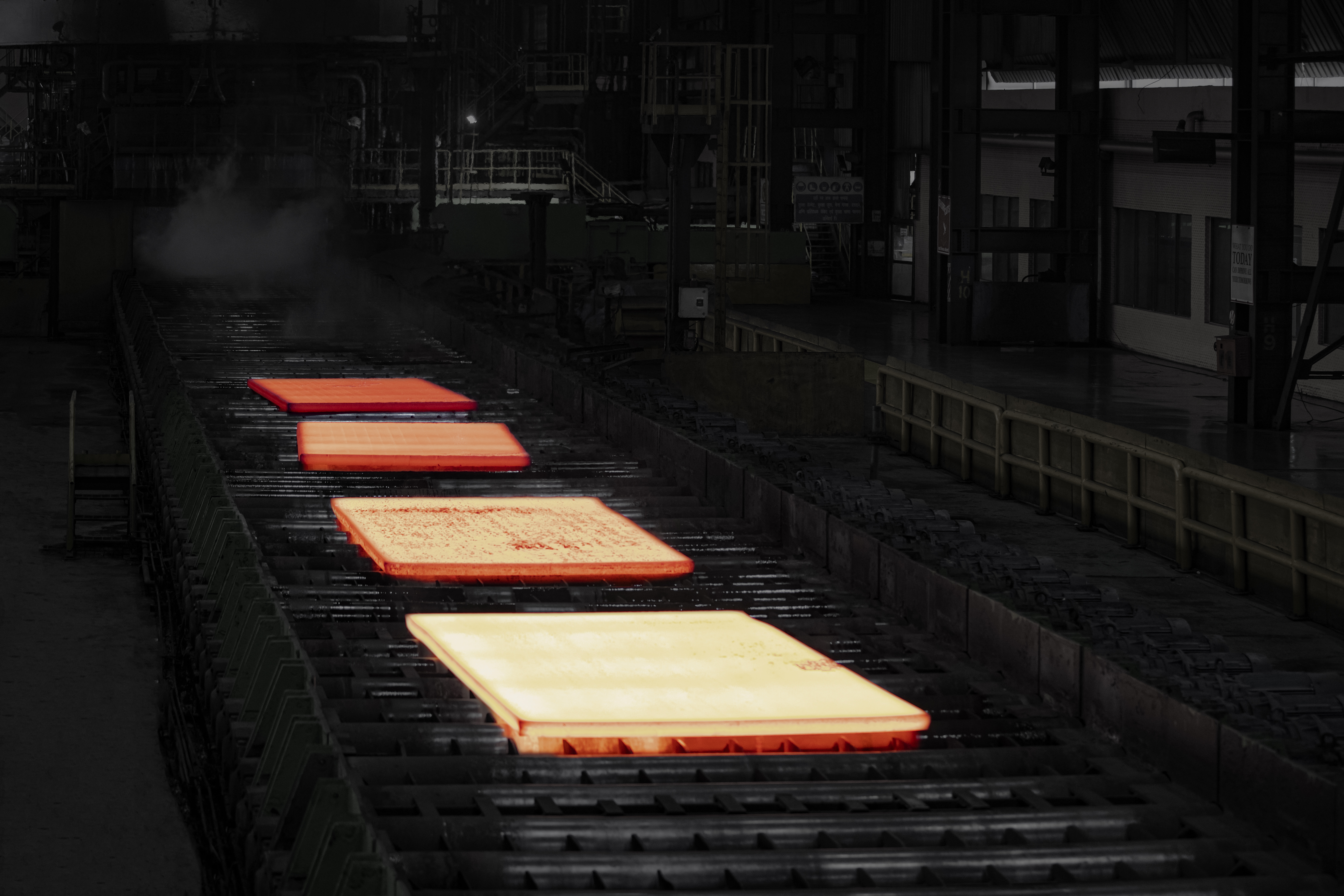

On a drawing, plate thickness appears as a simple figure. In the workshop, it decides how smoothly a job moves from raw stock to final fit-up. When the thickness is chosen carefully, MS plates, behave as expected, welders work at a steady pace, and the structure feels dependable without being unnecessarily heavy.

What factors should you consider when selecting the right MS plate? Let's find out here.

Why Plate Thickness Matters in Fabrication

Thickness is a balance between strength, rigidity, and fabrication effort. It affects how a part handles load and how it behaves under heat and force during cutting and forming. If too thin, the plates can warn around welds or buckle under loads. If too thick, the project's weight and cost increase, and handling becomes more difficult.

In workshop planning, thickness is tied to everyday decisions about plate fabrication, such as how parts are arranged on the plate, how the flame is set for cutting and how much bending the plate will take. Any mismatch between the drawing and real behaviour is usually noticed first in the cutting or fitting area.

Design and Performance Considerations

The starting point thickness selection is the design basis. Engineers review loads, part lengths, detailing rules, and relevant clauses in Indian Standards, then turn these into minimum plate thickness for each part.

Buyers also compare the required thickness with the standard rolling sizes offered by steel companies in India. Choosing sizes that are easily available can cut waiting time and make stock handling easier.

Key Factors to Consider Before Finalising Thickness

Thickness is rarely chosen by instinct alone. A fabricator who wants consistent results usually reviews the project's plate fabrication plan and verifies that the drawing, IS codes, and data shared by the steel plant in India are being followed

Some of the common factors include:

Design Loads and Codes

Refer to the design calculations and applicable IS codes to determine minimum thickness requirements, impact factors, and extra thickness for rust over time.

Cutting, Bending and Forming Processes

Determine whether the plate needs to be rolled, bent, or pressed. The machines's capacity, die radius, and bending allowance can limit the minimumand maximum thickness you can achieve.

WeldSize and Access

The way the plate edges are prepared, the gap between them aand the weld size all depend on thickness. A very thin plate can burn through, and a very thick plate needs more passes and preheat.

Handling and Lifting Arrangements

Crane capacity, yard layout, and available lifting tools can also limit the size and thickness of a plate you can safely handle.

Rust and Working Conditions

Incoastal, chemical, or very humid environments, you may need to increase the thickness to prevent the plate from rusting over time.

Workshop Checks Before Cutting

Once the material arrives at the workshop, it's your last chance to verify the hat numbers against the paperwork and confirm that the nesting plan is the latest revision. Begin cutting only after both checks pass.

On the floor, practicla checks often include:

- 1. Reading thickness with a guage at a few random points.

- 2. Checking the cut edge on a small test piece after a trial cut.

- 3. Comparing bend lines with press capacity and die set-up

Conclusion

Choosing the right thickness is not a guess; it is a series of small, careful decisions. When designers follow IS rules, when the workshop checks how MS plates behave during cutting and welding, and when buyers saty close to what a trusted steel plant in India can supply, the whole line of work becomes more stable.

Explore our latest Post